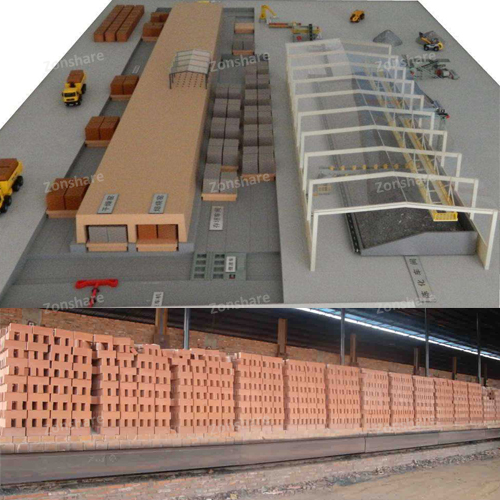

Tunnel kiln for automatic brick prouction plant

The tunnel kiln is a car pushing type continuous kiln consists of preheating,firing and cooling zones.It is suitable for a large production and is fabricated at the spot.

The advantage of using tunnel kiln in brick manufacturing is to provide the temperature conformity,lower the fuel consumption.

Design features and operational benefits are

l Consistent, high volume production from units

l High levels of control giving top quality products

l Low energy usage and lower cost production

l Computer controlled to make operation simple and reliable

l Low maintenance and minimal downtime

l Storage and handling systems for easy operation

l Reduced internal air movement for a better firing environment

A number of different methods can be used to heat tunnel kiln. The fuel can be gas,oil,coal and so on.Materials like bricks,tiles,and ceramics are some common products that may be mass produced with the aid of a tunnel kiln.Products like these may also be fired using an intermittent kiln, though that involves the benefit of a continuous process,such that some materials are beginning to heat at one end of the device,while others are being fired in the middle,and still more are cooling down at the far end.

Whatsapp/mobile:+86 18103842990